| View previous topic :: View next topic |

| Author |

Message |

MyChemicalRomance

Trick Member

Joined: 06 Sep 2008

Location: Currently Lost.... |

|

| Back to top |

|

|

CGRemakes

Basic Member

Joined: 23 Jul 2008

|

201.  Posted: Thu Feb 12, 2009 8:38 pm Post subject: Plexi on stealth pad? Posted: Thu Feb 12, 2009 8:38 pm Post subject: Plexi on stealth pad? |

|

|

| I was wondering if using 1/8" lexan on the stealth pad would work, or if it is too rigid and would cause the pad to not work, or work well. I would like to put a sheet of lexan and arrow graphics under it, but I don't know if this would cause a problem. Any thoughts? |

|

| Back to top |

|

|

devout

Trick Member

Joined: 15 Dec 2006

Location: the atl |

202.  Posted: Fri Feb 13, 2009 9:38 am Post subject: Re: Plexi on stealth pad? Posted: Fri Feb 13, 2009 9:38 am Post subject: Re: Plexi on stealth pad? |

|

|

| CGRemakes wrote: | | I was wondering if using 1/8" lexan on the stealth pad would work, or if it is too rigid and would cause the pad to not work, or work well. I would like to put a sheet of lexan and arrow graphics under it, but I don't know if this would cause a problem. Any thoughts? |

I dont know. I think it would still flex fine, but i'd be worried about it cracking. You have to crank down pretty hard on the screws to get the steel to pop up in the middle, and if you had lexan in there too im sure it would crack. so you'd probably need separate screws for the steel and lexan, which might be tough to work out, or come up with some way of padding the lexan so the screw doesnt crack it.

_________________

|

|

| Back to top |

|

|

CGRemakes

Basic Member

Joined: 23 Jul 2008

|

203.  Posted: Sun Feb 15, 2009 2:04 pm Post subject: Posted: Sun Feb 15, 2009 2:04 pm Post subject: |

|

|

| Another question I had, was on the width of the cardboard pieces for the steps. I'm trying to make them as thin as possible to lessen dead zones. I imagine, the position of the corner screws is directly proportional to the width of the cardboard piece to function correctly, right? I would like to have the corner screw in as far from the edges of the step as possible for strength, but at the same time, have the deadzone be as narrow as possible. What would be the proper "ratio"? The screw position must be closer to the edge than the inside edge of the cardboard? About the center of the cardboard strip? If I were to make the strips 1/4" or 3/8", I assume the screw would have to be 1/4" - 1/8" close to the edge, correct? Let me know if that doesn't make sense. |

|

| Back to top |

|

|

devout

Trick Member

Joined: 15 Dec 2006

Location: the atl |

204.  Posted: Tue Feb 17, 2009 8:31 am Post subject: Posted: Tue Feb 17, 2009 8:31 am Post subject: |

|

|

| CGRemakes wrote: | | Another question I had, was on the width of the cardboard pieces for the steps. I'm trying to make them as thin as possible to lessen dead zones. I imagine, the position of the corner screws is directly proportional to the width of the cardboard piece to function correctly, right? I would like to have the corner screw in as far from the edges of the step as possible for strength, but at the same time, have the deadzone be as narrow as possible. What would be the proper "ratio"? The screw position must be closer to the edge than the inside edge of the cardboard? About the center of the cardboard strip? If I were to make the strips 1/4" or 3/8", I assume the screw would have to be 1/4" - 1/8" close to the edge, correct? Let me know if that doesn't make sense. |

The screw should be centered at the center of the strip, or slightly closer to the edge of the step. The strip can probably be 1/4" wide, i wouldnt go thinner than that. I've never tried it though so it might not work. I'd make one and test it before you make all 4. The strip itself needs to be at least 1/8" from the edge though, so that also pushes the screw in 1/8".

_________________

|

|

| Back to top |

|

|

CGRemakes

Basic Member

Joined: 23 Jul 2008

|

205.  Posted: Tue Feb 17, 2009 5:21 pm Post subject: Posted: Tue Feb 17, 2009 5:21 pm Post subject: |

|

|

| Would 28 gauge steel work very well for this pad, or would it bend too easily and warp over a short time? I can get some 26 gauge, I just happen to have some 28 gauge already that is the right size. I may just have to try it, but if anyone knows whether this will or won't work, it would save me the extra effort of having to redo all the steps in a few months. |

|

| Back to top |

|

|

CT_Warrior

Trick Member

Joined: 28 Jan 2008

|

206.  Posted: Tue Feb 17, 2009 8:03 pm Post subject: Posted: Tue Feb 17, 2009 8:03 pm Post subject: |

|

|

Play it safe and get the 26 gauge or less.

I've read of some sheet metal warping somewhere in this thread. |

|

| Back to top |

|

|

CGRemakes

Basic Member

Joined: 23 Jul 2008

|

207.  Posted: Tue Feb 17, 2009 8:27 pm Post subject: Posted: Tue Feb 17, 2009 8:27 pm Post subject: |

|

|

| I can get either 26 or 24 for super cheap from my work (basically the same price). Did anyone ever determine if 24 will work? I'm shooting for durability with this pad, so if 24 works, I will get that. |

|

| Back to top |

|

|

Bpdude

Basic Member

Joined: 20 Feb 2009

Location: USA |

208.  Posted: Sat Feb 21, 2009 8:43 am Post subject: Homepad First Timer Posted: Sat Feb 21, 2009 8:43 am Post subject: Homepad First Timer |

|

|

Hey, I just built this as my first homepad. It took me like 10 hours but it works great  . I added some D-sub connectors and a project box to make it look a bit cleaner. I can only do 8 step or less songs on ITG (I play on PC) but this pad rocks (especialy compared to my softpad)!!! . I added some D-sub connectors and a project box to make it look a bit cleaner. I can only do 8 step or less songs on ITG (I play on PC) but this pad rocks (especialy compared to my softpad)!!!

Thanks to devout for the great instructions! |

|

| Back to top |

|

|

methejuggler

Basic Member

Joined: 05 Jun 2007

Location: Edmonton, Alberta, Canada |

209.  Posted: Fri Mar 13, 2009 1:03 am Post subject: Posted: Fri Mar 13, 2009 1:03 am Post subject: |

|

|

Looking for a good source of cheap pre-made control boxes!

(for those who don't want to read all this, maybe my question will still be answered if I put it first... now on to the main post)

Hey guys!

Been a while since I checked back here, and thought I'd post an update.

It's now been nearly 2 years since I built my pads, and they're still working GREAT!

In fact, I have many friends that keep wanting me to build pads for them, and they have friends, and so on... so I've been thinking of ways to improve the design, both for durability, reliability, and ease of manufacturing.

The new design doesn't use any wires in the actual device, and the panels are super easy to take off and on. All connections are done via the bolts which secure the panel, so once you take the bolt off, you can get into the panel for cleaning or maintenance with no fear of pulling wires and breaking soldered connections. Lack of wires also means, no fear of the sheet metal cutting into a wire accidentally as you place a panel, causing a short.

Here's what I've come up with:

- Use the 1" deep nuts, with a built in square or octagonal washer on one side. This way, you can drill a hole, insert most of the nut into the hole, with the washer at the back... and if you pick the right length of bolt, you won't have any ugly screws hanging out the back of your pad. Washer should pull into the wood enough that the back of the pad will be perfectly flat (with maybe a bit of indentation where the washers are).

- Use Aluminum Foil Tape instead of epoxying down tin foil. Much faster, easier, and may actually be cheaper (can get about 10-20 pads out of one roll of tape... you'd go through a lot of epoxy the other way). Not sure about the long term effects... ie. no idea how long before it may start pulling up and contact the sheetmetal... This needs to be tested.

- Use wide washer instead of a penny to clamp the tin foil tape in the recessed area, and a low profile head bolt to connect down to the bottom, underneith. Run aluminum foil tape under the nut/washer at the bottom of the pad to the top control area, and then another nut/washer to bring the connection back up above the pad in one corner to wire your "control box"... Washers clamp foil tape for firm connection, no wires to deal with. Easy to fix if it breaks (just buy a thing of aluminum foil tape for like $4 and re-run the connection - control box terminals on bottom would be labeled in case end user needs to redo more than one connection at a time).

- Use metal brackets at the bottom, and thread the bolt from the steps through the bracket on an angle between panels.... basically, you'd have 4 brackets, each connecting the inside corners of the 4 panels together. The nuts pull on the bracket, keeping tight contact. This becomes your ground connection - no soldering, no wires. Again, run one bracket off the top left of the up arrow on the bottom, and then another bolt up to connect into your "control box". The "brackets" could optionally be aluminum foil tape again, but I'd like to find actual thin 1.5-2" metal brackets (<1mm thick so it pulls into the wood again, slot running down the center to put bolts through).

- If you're using a recessed panel design (I recommend it), you only need to bend ONE side of the sheet metal panels (the side that's open air), just for safety reasons so you don't cut your feet on the sheet metal... the other 3 sides are butting up against wood anyway. Alternately, you can surround the whole pad in a thin strip of wood, and then you don't need to bend the sheet metal at all... big time saver, less hassle, and no worries of warping the panel.

- Use 24 gauge sheet metal instead of 26 for more durability, and less chance of warping. NOT TESTED! I plan on buying a few sheets of sheet metal soon at different gauge levels, and make up a few single panels, to test performance and durability, to find the best gauge for panels... I suspect that 24 should be fine though. I'll try as low as 20 gauge (although that starts getting more expensive, so a balance is needed).

- I'll be making up a "guide overlay" piece of poster board after my first successful pad with the new design, and punch holes where all drilling goes. Easily pre-drill all holes at the start, streamlining the process for future pads. If you're making up more than one pad, this could be something to consider.

- Buy a pre-made control box. This is where I'm stumped. I'd like to find a decent control box which connects to at least PS2 (majority of DDR games are on PS2), for fairly cheap ( < $20 )....

The soldering of wires to the controller to make my own control boxes will be the most time consuming part, and if I'm going to be pumping these out for all the people who want them, I want to keep construction time minimal, so I think a pre-made control box would save a lot of time, at a marginally higher cost.

Right now, with these changes, once the parts have been purchased, I estimate construction time at about 1 hour per pad, once I've done a couple and gotten used to it.

If someone can point me in the direction of a cheap control box with at least start/select buttons on it, I'd be very grateful =P

I'm hoping to get a few in this new design built up by the summer, in time for a local anime convention, and demo them there - I guarantee people would want to buy... every time I've gone in the past, they've had crappy soft pads in the games room.

Will mostly be selling locally at first, mostly to friends and such via word of mouth... but may consider selling elsewhere later... shipping costs would suck though... lol.

I'm actually not really in it to make money, more just that I've heard from several people who'd like one, and needed a faster and easier way to make them, since the conventional way would just take way too long and too much fiddling per pad for the number needed.

Main thing with the new design that I'm not particularly happy about is the aluminum foil tape running along the bottom for the connections. This would look ugly if you stood the mat up against a wall. I considered running it between the bottom plywood and the step panels instead, but the problem with that is you lose the firm connection that you get from clamping with a washer on the bottom. I suppose if I can find a good source of solid metal brackets for cheap, I can do a double bolt connection on the bottom, so that the connection goes down for the clamping, then back up under the pads into the space between, and travels along the inside... but that uses 8 brackets instead of 4, and extra nuts/bolts, which increases the cost. Would depend a lot on the price of each as to whether it would be worth it.

I'm toying with different ideas on how to easily connect multiple pads together, to make detachable doubles pads, too... I think that would be an awesome feature. Have a few ideas in mind, but haven't tested them yet to see how sturdy they are yet.

Any additions or more innovations to make construction faster and improve durability would be appreciated!

Once I actually start building these, I'll take pictures of the construction process and post them up with a new guide, as this new pad will be quite a bit different in construction than the original stealth pad. All credit still goes to Devout for his ingenious initial design though, of course :)

_________________

|

|

| Back to top |

|

|

slvrshdw

Trick Member

Joined: 05 Jan 2005

|

210.  Posted: Fri Mar 13, 2009 10:06 am Post subject: Posted: Fri Mar 13, 2009 10:06 am Post subject: |

|

|

Well, just a tip if you end up building your own CBs: don't use a ps2 controller, instead, use old soft pad's "brains" ;D

First of all, you only need the ULDR+start+sel+XO, all of which are on the soft pad controller boards.

Second, it's MUCH MUCH easier to use those to solder to, and it's usually smaller in the overall size.

They do sell extra control boxes online, but they are usually about 20 bucks or so, and you can easily make them for cheaper if you tried.

Depending on how many you need, I would be willing to help you out on making them. Just let me know.

(sidenote: what anime convention are you going to? I go to a bunch, and I am building 2 for someone who runs game rooms..just have the sensors left ;D)

_________________

|

|

| Back to top |

|

|

methejuggler

Basic Member

Joined: 05 Jun 2007

Location: Edmonton, Alberta, Canada |

211.  Posted: Fri Mar 13, 2009 12:09 pm Post subject: Posted: Fri Mar 13, 2009 12:09 pm Post subject: |

|

|

I've actually already built a few control boxes out of PS2 controllers (the MadCatz controllers work well)... just that the whole opening of the controller, drilling a hole for the cat 5 cable, trying to route in through the back and secure it inside to avoid pulling, soldering to connectors, etc takes a long time... at least 10 people have said they want one now, with several more who may be interested... add in word of mouth from there and it won't be long before I'll be needing to make lots fast...

Obviously old dance mats are the easiest, for sure, but it's not exactly easy to come across a large supply of these when you start getting lots of orders.

So, this is why I'm looking for a simple, cheap control box that I could rig up to. Where'd you see them for $20? Cheapest I've come across so far is $30...

Oh, and the anime cons I go to are all local in Edmonton, Alberta, Canada. Animethon is the one I was thinking of for the pads (unless they've already got hard pads this year, which is fine... I'm not looking to showcase that badly - just increases workload, lol)

_________________

|

|

| Back to top |

|

|

slvrshdw

Trick Member

Joined: 05 Jan 2005

|

212.  Posted: Sat Mar 14, 2009 8:15 pm Post subject: Posted: Sat Mar 14, 2009 8:15 pm Post subject: |

|

|

Actually, my friend got some cheap foam pads from ebay that eventually break down, so he kept the foam and circuit boards for me..so I have about 4 or 5 (?) now.

So, you can always ask friends for broken softpads and get them free that way, or check ebay for cheap softpads and break into those. I'm not sure on anything for bulk orders though, as I have never had to mess with them.

Another option that I found was really cool (also a really small PCB if you need it) was the "beat drum."

I found 2 of them at a gamestop for about $5 on clearance, so it's worth a try to check out used things at either EB Games or Gamestop (or if there's a Canadian equivalent...)

As for Animethon, good luck with that! I'm down in Texas, so I mostly go to Texas cons..and this year I get to go to Anime Central ;D

_________________

|

|

| Back to top |

|

|

methejuggler

Basic Member

Joined: 05 Jun 2007

Location: Edmonton, Alberta, Canada |

213.  Posted: Sat Mar 14, 2009 8:27 pm Post subject: Posted: Sat Mar 14, 2009 8:27 pm Post subject: |

|

|

Ahh, that's cool... I'll take a look around for sure.

Best I've found so far since my last post is from play-asia.com, they have a control box for $15, but still $10 shipping, so $25 USD per control box. That may be doable, but I'll keep my eyes open for other options.

Nice thing about these control boxes is that they have the start/select buttons on them... butchering a soft pad, I'd still have to make my own start/select buttons, which increases the cost again for the buttons.

May end up seeing if I can get a bulk discount from play-asia.com and order like 20 or 30 at a time. Not right off though - need to see how much demand I actually have for the pads first, and build some prototypes based on the new design (I've built several with the old design, but haven't tried my new modification ideas yet).

_________________

|

|

| Back to top |

|

|

MegaBeatManMania

Trick Member

Joined: 05 Dec 2002

Location: CHula VIsta CA |

|

| Back to top |

|

|

methejuggler

Basic Member

Joined: 05 Jun 2007

Location: Edmonton, Alberta, Canada |

215.  Posted: Sun Mar 15, 2009 9:03 am Post subject: Posted: Sun Mar 15, 2009 9:03 am Post subject: |

|

|

I have pics of mine in the link in my sig... several other people do that too. There really have been a fair number of pics of different versions of the stealth pad so far!

Haven't seen any videos of them yet though... hmm...

I'll probably get my brother to do a video documentation thing of me building one when I start back into it. He's done lots of films and stuff, so he'd probably enjoy it, and then you could see the full process if needed.

Good luck on your build! They're really not very hard to make, just can be a bit finicky to get all the steps to work sometimes.

_________________

|

|

| Back to top |

|

|

jmdbcool

Basic Member

Joined: 23 Mar 2009

Location: Phoenix, AZ |

216.  Posted: Mon Mar 23, 2009 1:50 pm Post subject: Posted: Mon Mar 23, 2009 1:50 pm Post subject: |

|

|

Hello DDR Freak! I used to be a member here a long time ago, but I guess my account was deactivated. I came back here looking for hard pad advice. I was thinking about buying a Cobalt Flux, but devout's brilliant, simplistic design has inspired me to (once again!) build my own pads.

I'm a pad-building veteran... I built 3 pads following ddrhomepad's original design, way back in 2002: two 4-panel pads, and one 6-panel. I sold all of them. I wasn't that satisfied with them-- each one was very responsive, but with all the lexan and the squishy feeling of the buttons, I was afraid that I was going to break it each time I played on it. The Stealth design looks solid and durable, and just makes a lot more sense to me.

I just started making 2 of these pads. I'm combining devout's design with methejuggler's ideas, and other thoughts from this thread. My pads will feature the following:

- Recessed arrows. The 4 arrow panels will be recessed by a very small amount, about 1/8 inch.

- Flat sheet metal with no bent-over edges. There will be a thin wood frame all the way around each pad, so all 4 edges of the metal will be recessed, leaving no need to bend over the edges.

- All arrow panels will be easily serviceable. The panels will be attached with bolts, not screws, to make them easily removeable, adjustable, and fixable. And to make it even easier...

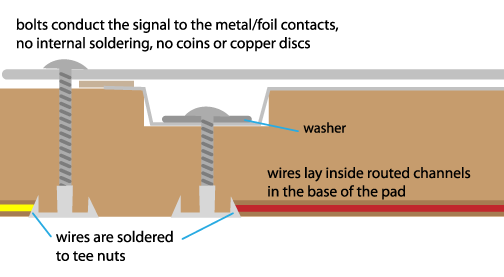

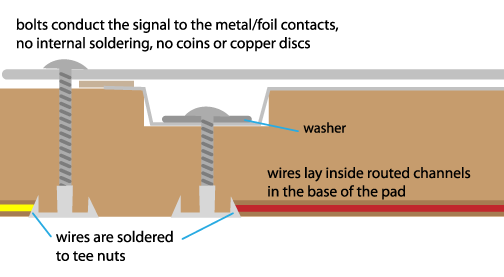

- All wiring will be done on the underside of the pad, with no wires between the arrows. Wires will be soldered to the tee nuts, set in the base of the pad.

- Completely flat bottom. I will countersink the tee nuts in the base, and use a dremel tool to route paths for the wires. The bolts should be just long enough to come down through the pad and catch the tee nuts, but not so long as to stick out the bottom.

methejuggler, I'm not sure what 1" deep nuts you were talking about, but that got me thinking of different ways to attach the panels, which led me to bolts and tee nuts.

(tee nut)

This way I can countersink/hammer in the nuts and they become a part of the base. Here's a concept diagram of how I want to do the wiring:

I promise I'll have lots of pictures and more details as I go.

_________________

|

|

| Back to top |

|

|

MegaBeatManMania

Trick Member

Joined: 05 Dec 2002

Location: CHula VIsta CA |

|

| Back to top |

|

|

Shuma Gorath

Trick Member

Joined: 15 Dec 2008

|

218.  Posted: Wed Apr 01, 2009 7:02 pm Post subject: Posted: Wed Apr 01, 2009 7:02 pm Post subject: |

|

|

| You make the solder joints on the front. On the black spots. You're supposed to scratch the black blobs with some sharp knife until you see some copper below the black blob. But doing that in that gamepad is really hard, because of the small balck spots. Better cash some 5 bucks and get some chinese psx controller, they have really easy to solder spots and you wont be ruining your precious shock controller. |

|

| Back to top |

|

|

MegaBeatManMania

Trick Member

Joined: 05 Dec 2002

Location: CHula VIsta CA |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

Powered by phpBB 2 © 2001, 2002 phpBB Group

|

. I added some D-sub connectors and a project box to make it look a bit cleaner. I can only do 8 step or less songs on ITG (I play on PC) but this pad rocks (especialy compared to my softpad)!!!

. I added some D-sub connectors and a project box to make it look a bit cleaner. I can only do 8 step or less songs on ITG (I play on PC) but this pad rocks (especialy compared to my softpad)!!!